WHAT ARE THE BENEFITS OF FOG SYSTEM IN TEXTILE SECTOR?

or the paper and textile industry it is important to achieve the right moisture balance. Moisture comes before everything to ensure that the products are productive, of high quality and without waste. As a matter of fact, one of the main reasons of possible problems is that the ambient conditions do not catch the right moisture. In this regard, fog systems provide the most suitable production environment.

- Provides optimum production by maintaining the correct moisture level.

- Reduces production time to minimum level.

- The humidity level of the environment reaches the desired balance.

- No paper curls or breakage due to the correct humidity and temperature.

- Static electricity, which may occur, is greatly removed from the environment.

Given all these factors, the fog system provides the most accurate support for capturing the production quota.

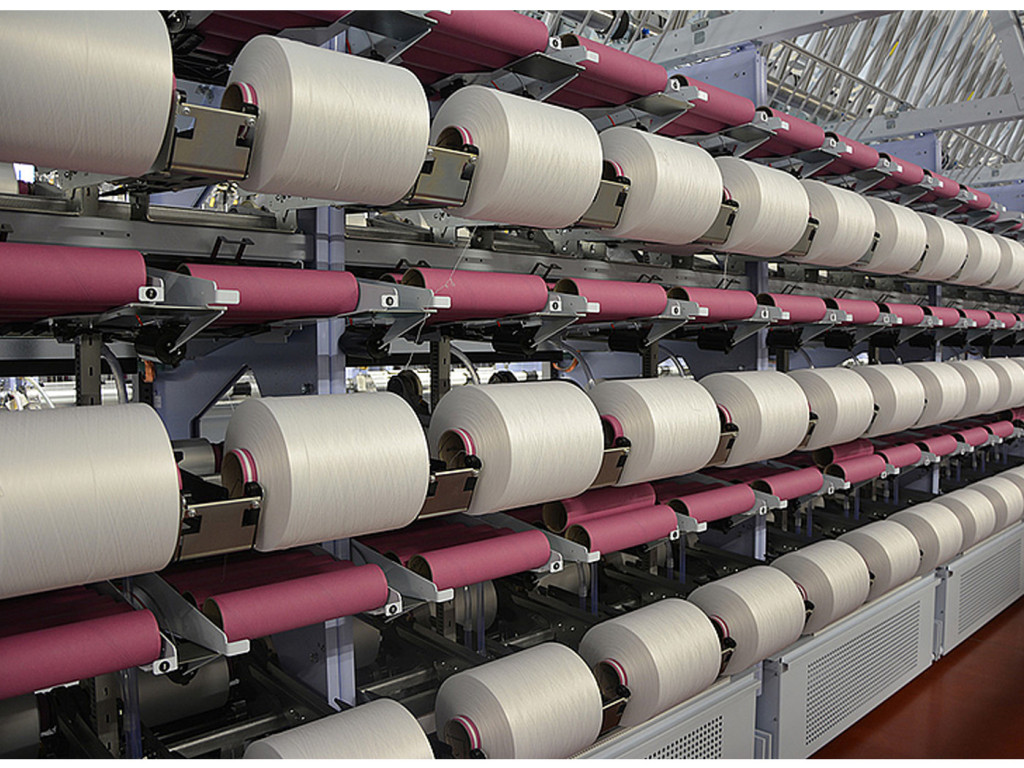

Fog Systems for Textile Industry

Fog nozzle systems which are designed with the best use of today's technology are of great importance for the textile sector. It provides a good quality product on behalf of textile products which produce moisture and humidity. These bends and breaks formed in the papers are largely eliminated. Thus, supply-demand can be met even at higher levels. Especially considering how high the demand for paper sector, moisture and moisture are indispensable factors in the textile sector. As a result, a balanced moisture environment must be established to achieve the desired moisture content. This system provides support over the water spray system with high pressure and provides an equal level of moisture balance for each point of the area. Thanks to the drip system, water droplets emitted to the production area evaporate to provide the most suitable environment.

Benefits of High Pressure Fog Systems in Textile Industry

More and more preferred fog systems throughout the world are of great importance especially for different products in the textile sector. Its benefits allow companies to achieve a more efficient production line.

- Static electricity is drawn to the minimum level.

- Adiabatic cooling is provided.

- Dust control

- Job stress is minimized.

- Efficiency is maximized and quality production is achieved.

- The best ink quality is achieved over an optimum amount.

When evaluating the high pressure fog systems, it is necessary to pay attention to the structure, production understanding and duration of the area.

Fog Systems Produced Through Professional Understanding

We offer a professional service on behalf of the textile industry in order to have a quality and efficient production area. The fog systems, based on international high standards, allow the optimum production line to become healthier. We provide high technology with an innovative approach through creative design and engineering planning. Scaling, production and transportation installation can be assured by our company. Together with the textile industry, we also offer high technology products for greenhouse areas through greenhouse humidification systems. After-sales service, customer satisfaction, long-lasting product and economic structure, we provide the best in the sector as the leader.